Screen printing is a technique that has been used for over a thousand years, to transfer decorative images to substrates such as fabrics. To manufacture the huge volumes of patterned materials economically, it has been necessary to design an innovative and dedicated process.

Screen printing is a technique that has been used for over a thousand years, to transfer decorative images to substrates such as fabrics. To manufacture the huge volumes of patterned materials economically, it has been necessary to design an innovative and dedicated process.

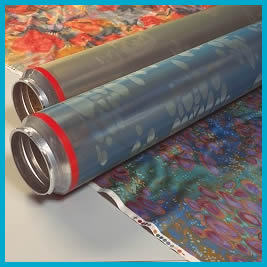

The technology involves transferring the inks of different colours that make up the decorative patterns to the substrate materials through perforated metallic rotating cylinders as shown in the image.

A typical cylinder consists of a long, thin-walled tube, typically 400mm in diameter and up to 4 metres in length. The cylinder wall thickness is only about 0.1mm and it vital that this is accurately controlled and consistent over their whole length and diameter.

In order to produce the required printing patterns, cylinders are manufactured with billions of tiny holes in their walls, ranging in size from 0.6 mm. down to 0.08 mm. in diameter.

Electroforming in nickel has proved to be the only method by which the cylinders can be manufactured to achieve this level of precision

Manufacture of screen printing cylinders has grown to become by far the largest single application of nickel electroforming in the world. An estimated 1,500 tonnes of metal a year are used for this application in Europe alone.

The perforated cylinders enable over 10,000,000,000 m2 of products such as fabrics, wallpaper and carpets to be printed each year.

For more information on Screen Printing Cylinders, please contact us.