The manufacture of thin products is an application almost tailor-made for nickel electroforming. Thin products, including plain foil, perforated foil and foam are deposited gradually from the first layer of atoms formed on the substrate surface until the required thickness is reached.

The manufacture of thin products is an application almost tailor-made for nickel electroforming. Thin products, including plain foil, perforated foil and foam are deposited gradually from the first layer of atoms formed on the substrate surface until the required thickness is reached.

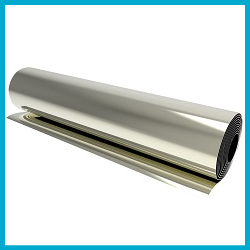

Plain Nickel Foil

Plain nickel foil is manufactured by continuous electroforming onto a cylindrical rotating mandrel that allows foil thickness to be accurately controlled, between 9µm and 100µm. As the forming process is continuous, the product can be produced in lengths up to 1,250 metres. Chemical and metallurgical properties of 99.95% pure nickel electroformed foils are comparable to those of foil products produced by conventional thermos/mechanical processes.

Electroformed perforated nickel foil

Electroforming technology enables perforated thin foils to be manufactured with a variety of hole geometry of carefully controlled size, shape and position. This is achieved by exposing the perforation area to visible light or UV radiation through an appropriately patterned mask. Selected areas of the resist are shielded from the radiation by a mask and therefore remain unaffected.

There is a wide range of applications for perforated nickel foil products, including sieves, inkjet nozzle plates, spray nozzle plates, electronic lead frames and foils for electric razors.

For more information on Nickel Foil, please contact us.